Schedule a demo with us

We can help you solve company communication.

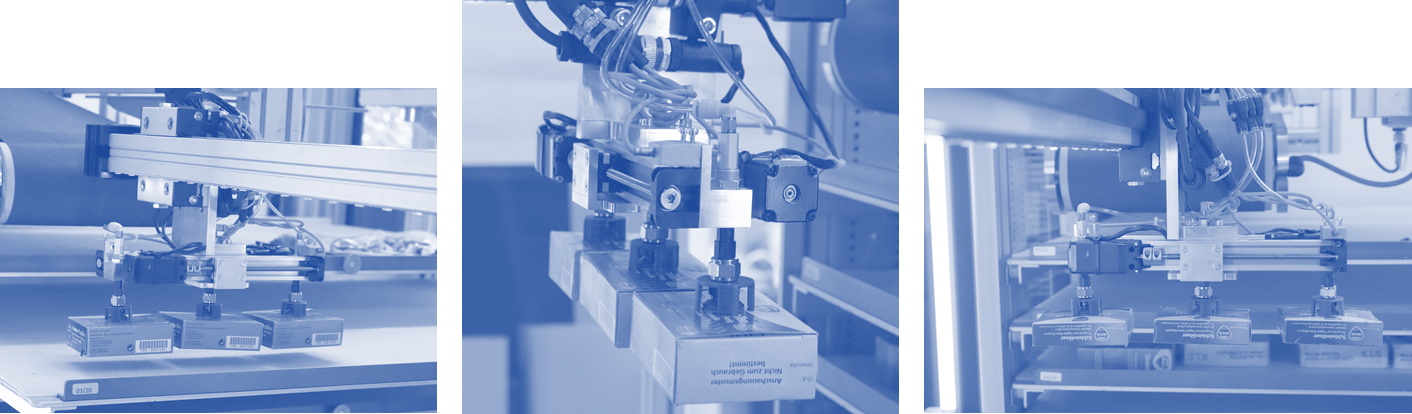

Wir sind der einzige Hersteller von Automaten mit einem 1000-fach bewährten Schubladensystem.

WELTNEUHEIT: Der KLS *3-fach* Multipicker Automat

|

Effektiv |

Runde und |

Zeitsparend |

*Markteinführung auf den Messen PharmagoraPlus (Paris, 11mar+12mar 2022) und Infarma (Madrid 30jun-02jul 2022).

|

E-Rezept Das digitale Rezept spart Zeit und Nerven. |

Kommisionierung & Verpackung Prozessoptimierung spart Kosten. |

Lieferung Der effektivste Botendienst der Stadt. |

Unsere Systeme sind für einen 24 Stunden Dauerbetrieb über mindestens 10 Jahre konstruiert. Zusammen mit der tadellosen Verarbeitung ergibt dieses Paket ein Optimum an Betriebssicherheit für Ihre Apotheke.

Wir sind die einzigen am Markt, die mit einem Schubladensystem arbeiten. Das führt zu unserem First In - First Out Prinzip. Unsere Automaten benötigen keine nächtliche Optimierung. Jede Packung kann sofort ausgelagert werden.

Unsere Systeme funktionieren auch dort wo andere nicht stehen können, wie Keller oder Obergeschosse, die oft durch eine geringe Raumhöhe sonst keinen sinnvollen Automateneinsatz zulassen.

kls

Solo ®

kls

Twin ®

kls

Slimline ®

kls

Quattro ®

Unsere Lösungen helfen Ihnen, Ihre Sicht- und Freiwahl zu virtualisieren und wertvolle Beziehungen zu Ihren Kunden aufzubauen.

K-Vision optimiert die Regale monatlich nach den Bestsellern. Sie haben keine Arbeit.

Lenken Sie die Aufmerksamkeit auf Angebote und Preisaktionen. Dazu haben Sie immer aktuelle Preise aus Ihrer Warenwirtschaft.

„Ich habe mich für KLS entschieden, weil die Anlagen sehr verlässlich und konstant laufen. Wir

haben uns Zeit gelassen und uns immer wieder informiert und dann fiel die Wahl auf KLS. Ich

bin froh, dass wir die Entscheidung getroffen haben.“

Doris Schwaabezur Website

SaniPep Apotheke im Einkaufs-Center Neuperlach

Kunden täglich

Kassen im Einsatz

Packungen im Automaten gelagert